The Economic Order Quantity (EOQ) formula is a tool for businesses to determine the ideal order size to minimize inventory costs. It strikes a balance between ordering too often (which increases costs per order) and ordering too much (which raises carrying costs like storage and insurance).

If you manage a product-based business or work in supply chain logistics, EOQ gives you a simple way to reduce waste and meet customer demand more efficiently. Instead of guessing how much to order, you use a proven formula — based on demand, fixed costs, and storage costs — to find the optimal number of units per order.

How to Calculate EOQ (Without Overcomplicating It)

Getting your economic order quantity right starts with just three numbers. You don’t need a finance degree — just a calculator or spreadsheet and basic business data.

First, here’s what you’ll need to know:

- **How many units do you sell each year **(your annual demand)?

- How much does it cost to place an order, no matter the size? What is your cost per order?

- What does it cost to store a single unit for a year (also called the carrying cost or holding cost per unit)?

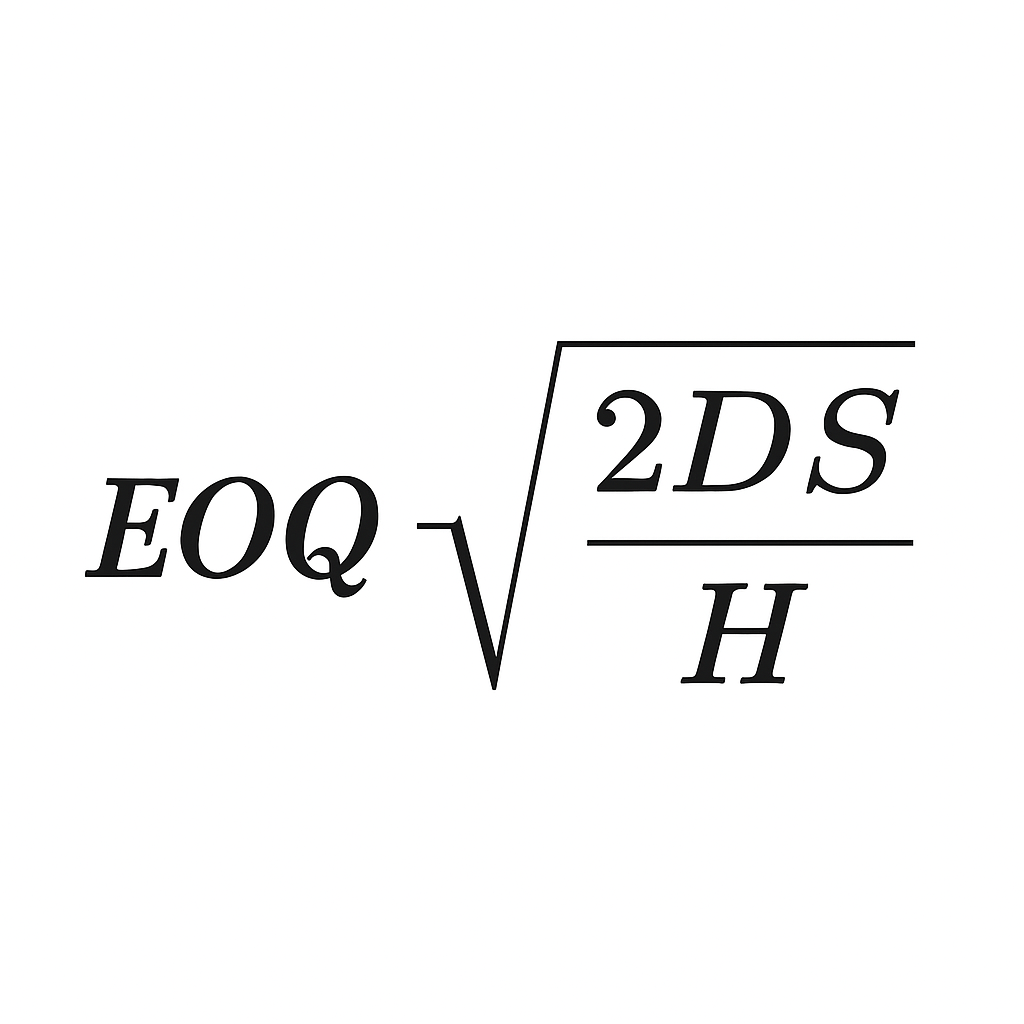

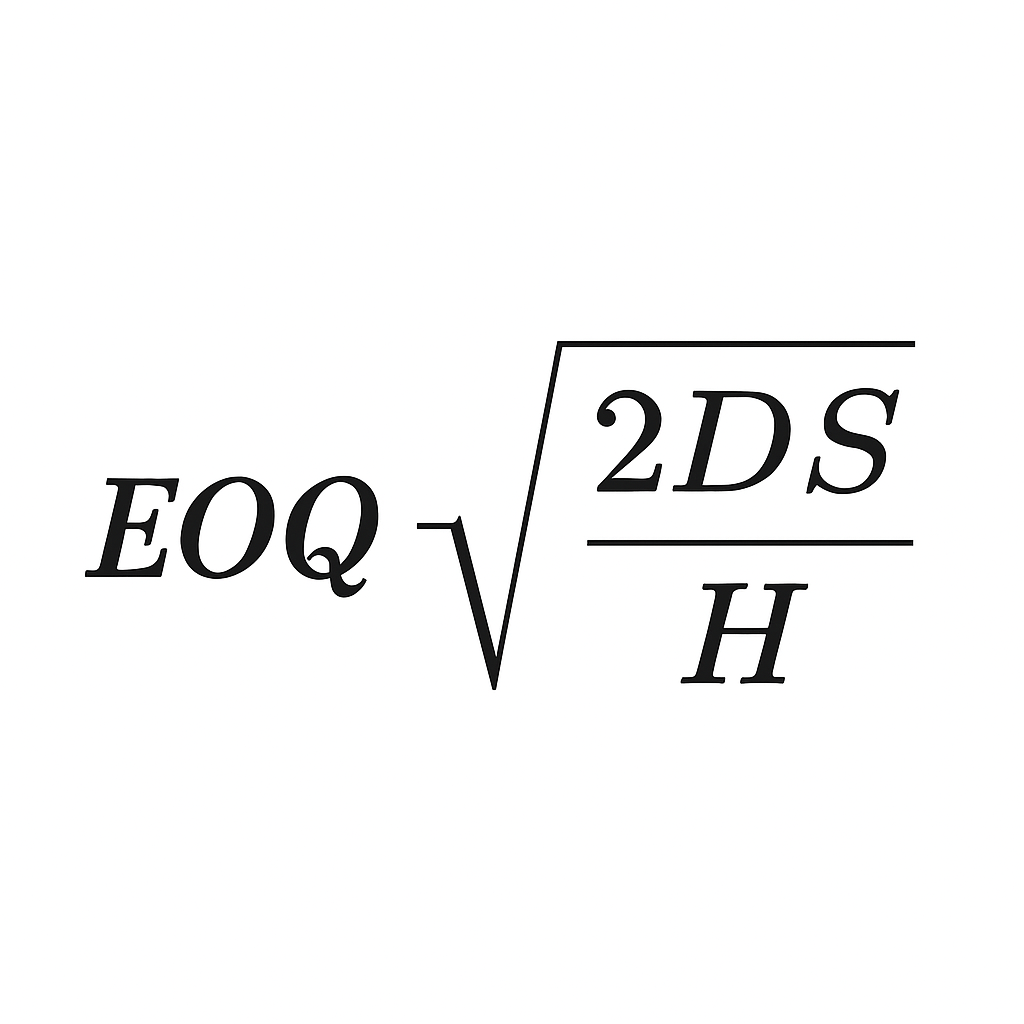

Those three numbers plug into this formula:

- D: your annual demand (in units)

- S: your setup or ordering cost (a fixed cost)

- H: your holding cost per unit per year

Let’s walk through a quick example. Say you sell 10,000 units per year. It costs $50 to place an order and $2 to store each unit for a year. Plug those into the formula:

That means your ideal order size (the one that minimizes total inventory costs) is around 707 units per order.

Why the Square Root?

The square root in the EOQ formula balances frequency and volume. More frequent orders drive up setup costs. Larger, less frequent orders increase storage costs. EOQ finds the sweet spot — where both costs are lowest.

A few things to keep in mind:

- The EOQ formula gives you the optimal number of units based on fixed, predictable inputs. If your demand fluctuates or your costs change often, you'll want to revisit it.

- Some rounding is normal. Ordering 700 or 725 probably won’t break your budget, but knowing that range helps avoid guesswork.

- This is a model, not a rulebook. Use it to guide better decisions, not lock yourself into rigid habits.

Why Use EOQ: Key Benefits and Real-World Use Cases

There’s a reason the EOQ model has stuck around for years: it works.

For businesses that hold inventory, EOQ helps answer one of the most expensive questions:

How much should we order — and when?

Without it, most companies either overstock (and pay too much in carrying costs) or order too often (which raises fixed costs). EOQ helps you avoid both extremes by calculating the ideal order size — the number that keeps inventory lean without risking shortages.

Here's what EOQ helps you do:

- Lower total inventory costs by reducing wasteful orders and excess stock

- Meet customer demand reliably without having to rush or overpay for last-minute shipments

- Optimize storage space so you're not paying for inventory that just sits there

- Balance cost per order against annual holding costs per unit, which are often overlooked in day-to-day decisions

EOQ applies across multiple industries.

- In ecommerce, where margins are tight and space is limited, EOQ helps prevent over-ordering slow-moving products.

- EOQ in manufacturing ensures that raw materials arrive in sync with production schedules.

- And in retail, it keeps shelves stocked just enough to meet demand — but not so much that items go stale or out of season.

When EOQ Works (and When It Doesn’t)

The economic order quantity model is powerful. But it’s not perfect.

EOQ works best in stable environments when your unit demand is relatively steady, your cost per order doesn’t change much, and your carrying costs are predictable. In other words, it thrives in calm waters.

When EOQ fits like a glove:

- You sell the same products year-round

- You know your fixed costs and storage costs upfront

- Your supply chain isn’t volatile

- You want a consistent method to lower total inventory costs

In those situations, EOQ becomes a smart baseline equation that helps you avoid over-ordering while still meeting customer demand.

But it’s not for every business, every time.

When EOQ might fall short:

- Your demand fluctuates dramatically from month to month

- Lead times are unpredictable, and stockouts cost you more than overstock

- Storage capacity is limited or expensive

- You work with perishable goods or short life cycles

The math might still be helpful in those cases, but you’ll likely need to layer in other models or adjust your safety stock manually. EOQ doesn’t handle surprise disruptions well. It assumes a predictable world.

So, use EOQ as a baseline, not a blindfold. It’s a great starting point, especially for high-volume SKUs or core inventory. Just know when to flex around it.

EOQ and Inventory Strategy: Putting It Into Action

Knowing your EOQ is helpful. But knowing how to use it — that’s where the value kicks in.

EOQ doesn’t replace your entire inventory strategy. Instead, it gives you a smarter foundation. It helps you order the optimal number of units — not too many, not too few — to keep inventory costs low while still delivering on customer expectations.

###Think of EOQ as the control center.

You can use it to:

- Set default order sizes for high-volume items

- Plan reorder points around consistent demand in units

- Align with other tools like safety stock and lead time buffers

- Keep your total costs in check — especially as your supply chain grows more complex

It also works well alongside automation. Many inventory management systems let you plug in EOQ values to help guide purchasing decisions — directly or by syncing the logic behind it.

Common pitfalls to avoid:

- Assuming EOQ is always static: If your annual demand changes, so should your EOQ. Revisit it regularly.

- Ignoring hidden costs: If your storage costs or handling fees rise, your EOQ might need adjusting.

- Treating EOQ as a silver bullet: It’s a tool, not a solution for every inventory challenge. Combine it with real-time data and human oversight.

When used right, EOQ keeps your operations lean without risking lost sales. It’s not the only number that matters, but it’s one you don’t want to ignore.

Bottom Line

Let’s recap the essentials:

- EOQ is based on your annual demand, cost per order, and carrying cost per unit.

- The **EOQ formula **gives you the **optimal number of units **to order each time.

- It helps balance fixed costs and storage costs, so you’re not over- or under-ordering.

- It’s best used in stable environments and regularly updated as conditions shift.

Looking for a smarter way to manage inventory?

Explore Tailor’s inventory management system to automate EOQ and optimize your supply chain. Or schedule a demo to see how it works for your business.