Inventory is what keeps your business moving — the line between a smooth operation and complete chaos. When it’s off, everything feels harder. And yet, a lot of businesses are still relying on clunky tools that were never built to keep up. The issue isn’t always the system itself; it’s that the system wasn’t built to evolve with you.

Rigid, monolithic software might’ve been fine in the early days of your business. But scaling demands operational clarity, cross-functional alignment, and real-time responsiveness. More visibility. More automation. More integration. More control. And most importantly, more flexibility.

Let’s talk about how strategic inventory management can unlock scalable growth — and how your team can implement it without the growing pains.

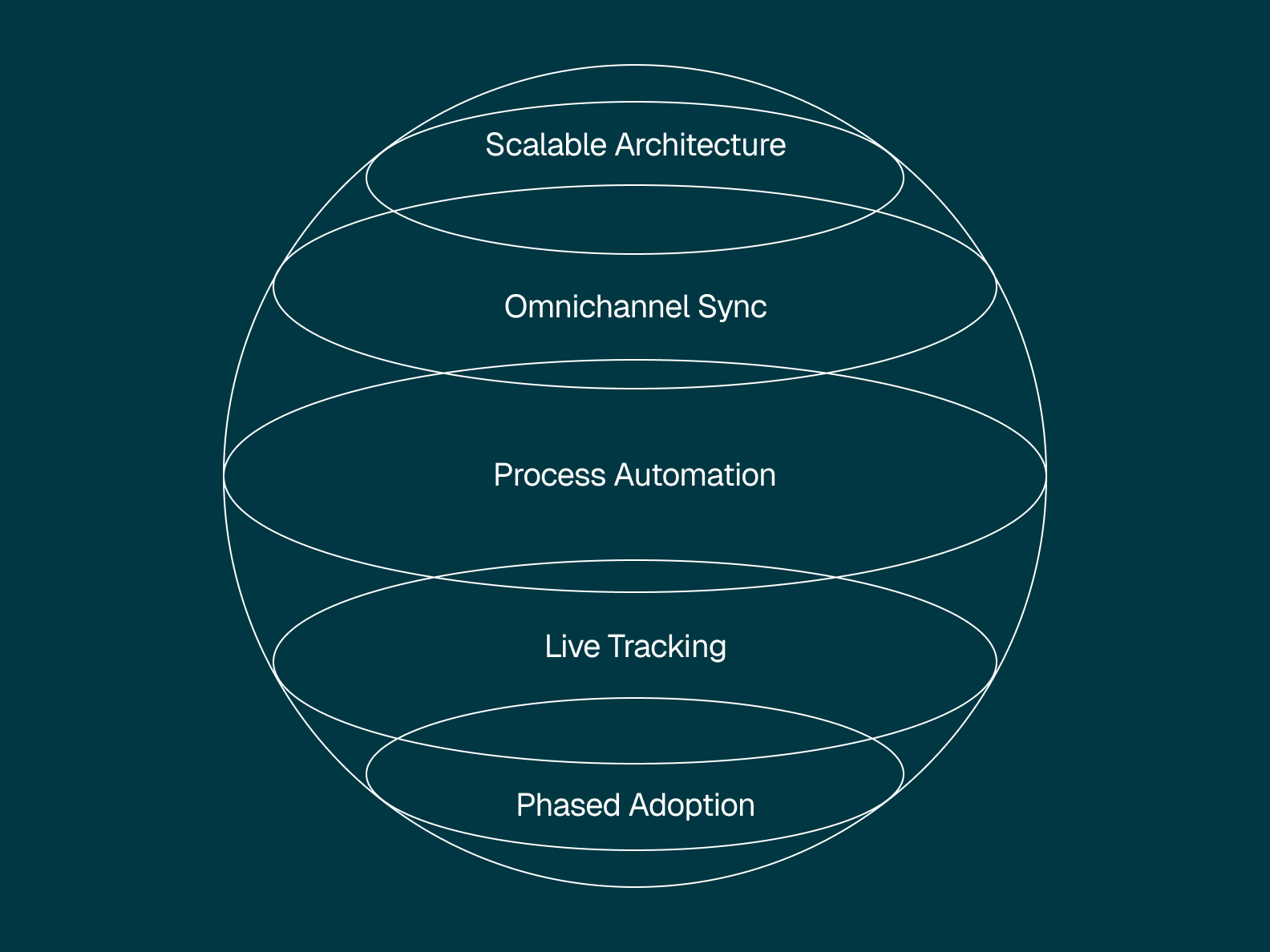

Build on systems that scale with you

Growing a business means lots of change: new products, new channels, and new ways of doing things. If your systems can’t keep up, they’ll slow you down. Your organization needs tools that grow with you and don't force you to jump through hoops every time you try something new.

That’s where modular, API-first platforms deliver, giving you the ability to build exactly what you need and nothing you don’t — so you can add functions, remove friction, and integrate with what’s already working. It’s a plug-and-play approach that lets you future-proof your operations without blowing everything up every time you hit a new growth phase.

Traditional systems make you choose between two equally painful paths: commit to a bloated all-in-one ERP or duct-tape together best-of-breed tools that never really talk to each other. Neither path works at scale.

With a composable retail operations platform like Tailor, you don’t have to choose. You can integrate best-in-class tools for ecommerce, logistics, accounting, and customer service while still maintaining a single source of truth — your operational core.

Choose tools that grow with you:

- Look for modular architecture.

- Prioritize integrations over replacements.

- Avoid systems that lock you into fixed processes.

- Invest in platforms that enable custom workflows without custom dev work.

Integrate across every sales channel

You don’t just sell in one place anymore (or maybe you never did). Shopify. Amazon. A brick-and-mortar spot downtown. TikTok Shop. Wholesale orders that come in via email. Wherever customers are, your inventory has to be right — not by the end of the day, but in real time.

But too often, businesses try to duct tape a solution together. A little QuickBooks over here. A little Excel over there. A third-party plugin that sort of works when the wind’s blowing the right direction. The more you scale, the shakier this foundation becomes. Each additional channel introduces more risk: overselling, fulfillment errors, inaccurate lead times, unhappy customers. That’s an operational nuisance and a revenue killer.

An inventory management system that offers true omnichannel integration doesn’t just sync — it connects. That means real-time data flowing between systems, automatic stock adjustments, centralized visibility, and fewer fulfillment disasters waiting to happen.

Integration headaches, solved:

- Centralize your inventory across all platforms.

- Use an API-first system for seamless data flow.

- Get alerts before a channel oversells a product.

- Sync fulfillment and shipping data to reduce delays.

- Connect demand forecasting tools to purchasing workflows.

Modern inventory systems should be built with marketplaces, B2B portals, and DTC stores in mind. Tailor lets you connect them all through one hub, whether you’re selling printed t-shirts or personalized pet ID tags.

Automate the grunt work

Manual processes kill efficiency. Every time someone has to manually update stock levels or chase down a misplaced SKU, your business bleeds time and money. Enter automation.

Good inventory automation doesn’t take away control — it gives you more of it. Set automation rules that optimize inventory movement across locations, channels, and fulfillment methods, while giving leadership visibility into what’s driving performance.

But here's the best part: You get to decide what to automate and how it should behave, not be stuck with someone else's idea of how your workflow should function.

Automation advantages:

- Reduce human error across inventory adjustments and order fulfillment.

- Save time on tedious tasks like replenishment and cycle counts.

- Automate cross-channel reconciliations.

- Enable smarter decision-making through dynamic reorder logic.

- Free up operational teams to focus on strategic initiatives like supplier negotiations, margin improvements, and merchandising optimization.

Automation isn’t about replacing your team — it’s about amplifying what they’re capable of.

Make real-time insights your new baseline

In the old days, you’d run an inventory report at the end of the week and hope for the best. But now? That kind of lag could sink you. Between fast-moving consumer expectations and razor-thin margins, you need insights that are up to the minute, not outdated by the time they hit your inbox.

Real-time inventory systems turn every SKU into a data point you can act on. You can see what’s flying off the shelves, what’s sitting too long, and what’s at risk of running out — all in one place, and all as it happens.

Better yet, AI-native systems go beyond the dashboard. They surface trends you might not catch on your own, flag anomalies before they become issues, and help you make smarter purchasing and pricing decisions.

Features to look for:

- Real-time tracking of all stock levels and locations.

- Predictive analytics for demand planning.

- Automated low-stock alerts and reorder suggestions.

- Intelligent replenishment recommendations based on historical and seasonal data.

- Dashboards customized by role: ops manager, buyer, warehouse lead, and more.

Real-time visibility means better communication across departments. When marketing knows what’s in stock, they can promote more intelligently. When customer service has accurate inventory data, they can resolve issues faster. It’s a win-win, both from an ops standpoint and a business standpoint.

Ditch the spreadsheets — without losing your mind

Look, nobody’s judging you for using Excel. It’s familiar, and it works (until it doesn’t).

But at a certain point, managing inventory with spreadsheets or entry-level software like QuickBooks becomes an operational liability. Shifting to an ERP-based or integrated inventory system will allow you to replace disconnected tools with a system that ties everything together: orders, vendors, fulfillment, accounting, forecasting — the works.

We know change is hard. But that’s why Tailor emphasizes modular adoption — so you don’t have to do it all at once. Start by syncing your inventory data and gradually bring in automation, forecasting, and channel integrations as you go.

Make the transition smoother:

- Audit current systems and processes to identify gaps.

- Map out integration points: Shopify, QuickBooks, warehouse tools, etc.

- Choose a platform that supports modular adoption and phased rollouts.

- Support cross-functional adoption with clear training plans and role-specific onboarding.

- Track ROI metrics as you go (e.g., time saved, error reduction, order accuracy).

Don’t let the fear of a complex transition keep you tied to tools that are slowing you down.

Take action to improve now, and future-proof later

Improving your inventory operations doesn’t always mean a full-blown digital transformation. Start small. Tweak a workflow. Automate a single process. Unify just one data stream. Then build from there.

Here are a few steps to get started:

- Set benchmarks for fulfillment time, error rates, and stock accuracy.

- Identify bottlenecks — where are people wasting time or correcting mistakes?

- Explore automation opportunities in returns, order routing, and low-stock alerts.

- Integrate key platforms like e-commerce, warehouse management, and accounting.

- Review forecasting tools to better anticipate seasonal or promotional swings.

- Track inventory performance by channel — what’s profitable? What’s dragging you down?

- Eliminate redundant tools that cause data silos or manual double-entry.

- Identify blockers to scale — and prioritize automation that reduces cost, increases visibility, or improves lead time.

Each of these steps will make your system stronger, and together, they’ll make your business future-proof.

Bottom line: Systems should unlock growth — not block it

The best inventory management strategies are about more than keeping your shelves stocked and orders on time — they’re about building a business that can scale without chaos. One that aligns inventory operations with business goals and delivers clarity, speed, and control as you scale.

That takes a system built to support you, not one that boxes you in — and that’s where Tailor comes in. Our API-first, AI-native retail operations platform is designed to help you automate what matters, integrate what works, and grow without compromise.

Ready to optimize your inventory management so your business can thrive?

Schedule your demo with Tailor today.